Research Projects:

2- Development of model for viscoelastic behavior of epoxy/3D carbon fiber

3- Residual stresses prediction in 3D interlock composites manufactured by resin transfer molding

4- Development of SiC/SiC Ceramic Matrix Composites

5- Noise and vibration control

6- Surface finish characterization

8- Invention of new methods for manufacturing ceramic composite materials

9- Optimisation of slurry rheology and formulation for Ox-Ox and SiC-SiC ceramic composites

10- 3D printing of smart nanocomposites containing remote sensors for stress monitoring

A

A

Experimental study and modeling of porosity formation by volatile compounds generated during thermosetting of composite parts

A composite consists of a heterogeneous mixture of two or more components to form a new material which has better properties than each of its components and whose specific properties (eg rigidity / weight ratio) are much higher than those of traditional materials such as metals. Nowadays, new liquid molding processes such as RTM (Resin Transfer Molding) are increasing in aircraft manufacturers because they allow to obtain high quality parts at a lower cost. This method has several other advantages such as the flexibility of design allowing the use of new three-dimensional reinforcements instead of the usual multilayer laminates. These 3D reinforcements give rise today to new structural applications of reinforced composites. The formation of porosities during the manufacturing of composites by the RTM process can be controlled and even eliminated in order to minimize the risk of material failure. These porosities result from two well-identified causes: (1) they can be formed by inclusion of air during impregnation of the reinforcement; or they may be generated by the volatilization of gases from the polymerization chemical reaction. In both cases, the minimization of these porosities is an important problem, which must be checked to ensure the certification of aerospace parts. In order to overcome these disadvantages, it is possible to optimize the RTM molding conditions so that (1) no porosity is formed by inclusion of air and (2) the organic components of the resin do not volatilize, thus ensuring the elimination of the second cause of porosity formation.

This project aims to study the formation of porosities in various composite parts using different materials from the aerospace industry. The main objective is to demonstrate the existence of optimal conditions for the production of high-performance composites by the RTM process and to implement them to demonstrate their potential in industrial applications. This ambitious but realistic goal will allow us to better understand the behavior of new aerospace materials such as three-dimensional carbon reinforcements and the new phenolic and epoxy resins used in the manufacture of structural aeronautical parts. The different experiments will allow to develop a numerical model allowing to predict the behavior of the porosities of chemical origin during the manufacturing of composites. This model will also optimize process parameters such as thermal cycle and pressure cycle.

A

| Group members | |

| Leader: | Cédric Pupin |

| Supervisors: | Prof. Edu Ruiz |

| Prof. Annie Ross | |

| Prof. Charles Dubois | |

| Industrial Partner: | Safran Group |

A

A

A

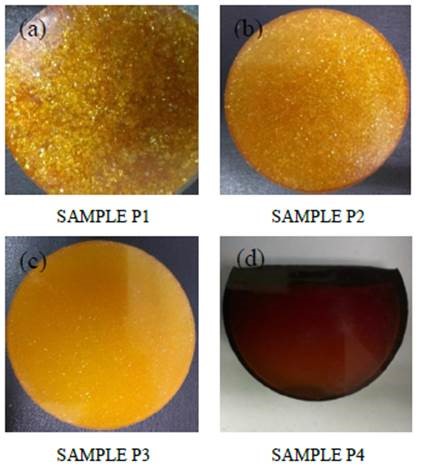

Development of model for viscoelastic behavior of epoxy/3D carbon fiber

This project consists of developing a behavior model for a composite material made of an aerospace epoxy resin and a 3D interlock woven carbon fabric. The model will be used in numerical tools to predict the development of residual stresses during the manufacturing of composite parts by Resin Transfer Molding (RTM). Residual stresses, mostly due to volume changes in the material (thermal expansion, shrinkage…) and interactions between the mold and the part, could lead to unwilling deformations. Temperature and degree of cure evolve during the process, changing the resin properties. A temperature and degree of cure dependent viscoelastic model is then required to predict more accurately the residual stresses development.

First, rectangular pure resin specimens were manufactured at different degrees of cure and tested with a Dynamic Mechanical Analyzer (DMA). Isothermal relaxation tests were carried out at several temperatures. A model was developed based on the linear viscoelastic constitutive theory, using Prony series. Temperature and degree of cure dependences were added according to the relaxation results. Moreover, the viscoelastic model is implemented in the finite element software ABAQUS, using differential strategies. The homogenized properties of 3D interlock woven composites could then be determined. Finally, the homogenized properties will be validated through isothermal creep tests in tension on composite specimens.

A

| Group members | |

| Leader: | Alice Courtois |

| Supervisors: | Prof. Edu Ruiz |

| Prof. Martin Lévesque | |

| Industrial Partner: | Safran Group |

A

A

A

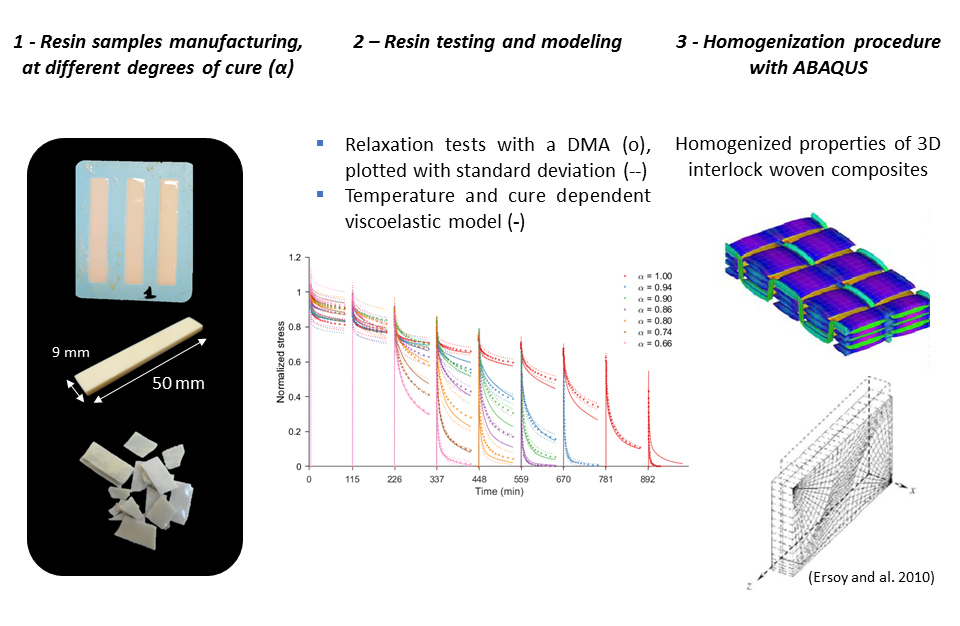

Residual stresses prediction in 3D interlock composites manufactured by resin transfer molding

Residual stresses are inherent to the manufacturing of composite parts; their presence can generate geometrical instabilities and/or modify the mechanical performance of the part. Resin’s chemical shrinkage, differences in the coefficients of thermal expansion (CTE) between fibers and matrix and the interaction between part and tooling are known to be the main mechanisms responsible for the residual stresses generation during molding. This work focuses on the development of a fully integrated simulation code to compute the residual stresses evolution during the RTM (Resin Transfer Molding) manufacturing of composite plates reinforced with Three-Dimensional (3D) interlock fabrics. Mechanical and thermal homogenized models will be implemented into a commercial FE package, Abaqus. The code will be validating by simulating the residual stresses generated in an asymmetric plate reinforced with 3D interlock fabric. The models distortion prediction will be compared against the experimental distortion encountered in a real component. The plate’s deflection dependence with the temperature, time and material will be analyzed over the work. The final aim of the project is to use the developed simulation code to predict accurately the residual stresses built-up in aerospace structural parts reinforced with 3D interlock fabric.

A

| Group members | |

| Leader: | Maria Benavente |

| Supervisors: | Prof. Edu Ruiz |

| Prof. Martin Lévesque | |

| Industrial Partner: | Safran Group |

AAAaaa

aAA

A

Development of SiC/SiC Ceramic Matrix Composites

Ceramic matrix composites (CMC) are well known for their high temperature resistance. SiC/SiC composites have the ability to be operated at much higher temperature than metallic alloys, along with a significantly lower density, which confer them very high potential for applications in turbofan and rocket engines. However, traditional SiC/SiC composites are very expensive and labor consuming.This project aims at developing an innovative process for manufacturing SiC/SiC ceramic composites with a considerable cost reduction. Based on the knowledge acquired on oxide/oxide ceramic composites, this project aims at studying various phenomena’s of the process. The flow behavior, the green body formation and the impregnation of the fibrous reinforcement can be characterized during the process by combining different characterization methods (rheology, pH, X-Ray diffraction, TGA, etc.) in conjunction with a specific measurement cell. In addition, the project focuses at understanding the capillary infiltration of a liquid metal at high temperature in order to model the flow behavior during processing of these CMC materials. A mathematical modelling is also proposed to predict the flow behavior in liquid infiltration.

AA

| Group members | |

| Leader: | Isabelle Ortega |

| Supervisor: | Prof. Edu Ruiz |

| Industrial Partner: | Safran Ceramics |

A

A

A

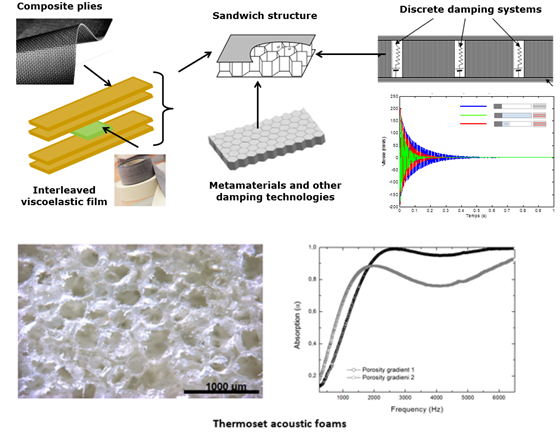

Noise and vibration control

The high specific properties lead to an increasing use of composites materials in almost every engineering fields. However, the lightness eases the propagation of mechanical and acoustic vibration that can lead to failure or discomfort. This aspect of my research activities has dual objectives; developing the proper damping devices and noise absorbing materials and developing manufacturing techniques to ease their integration into composite structures.

AA

| Group members | |

| Leader: | Edith Roland Fotsing |

| Supervisors: | Prof. Edu Ruiz |

| Prof. Annie Ross |

aaa

A

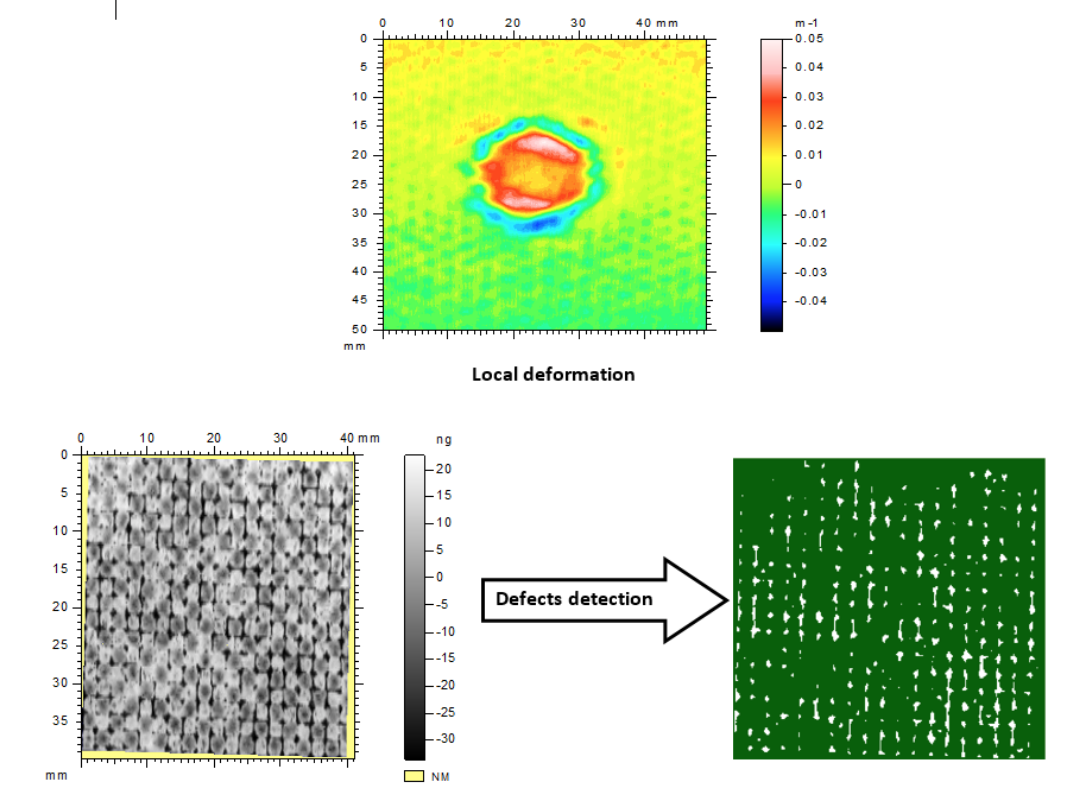

Surface finish characterization

Beside the remarkable mechanical properties, surface finish is one of the most important parameters of quality control of composite materials. The surface finish not only improves the esthetic of the part but also the quality of the assembly. If there are several non-destructive techniques to characterize damage in composites (e.g. ultrasound), characterization techniques of surface finish are very limited. This is because the perception of the surface quality is highly subjective and the decision to accept or reject a composite part depends on the standard used. It is therefore necessary to establish objective metrology techniques based on quantifiable and measurable data. As such, curvature is the physical quantity representing the local defect (deformation) as perceived by the human eye. The main objective of this project is to establish a clear correlation between the surface finish quality, the material properties (resin shrinkage, resin-curing cycle etc.) and manufacturing parameters (pressure, temperature).

AA

| Group members | |

| Leader: | Edith Roland Fotsing |

| Supervisors: | Prof. Edu Ruiz |

| Prof. Annie Ross |

aa

a

A

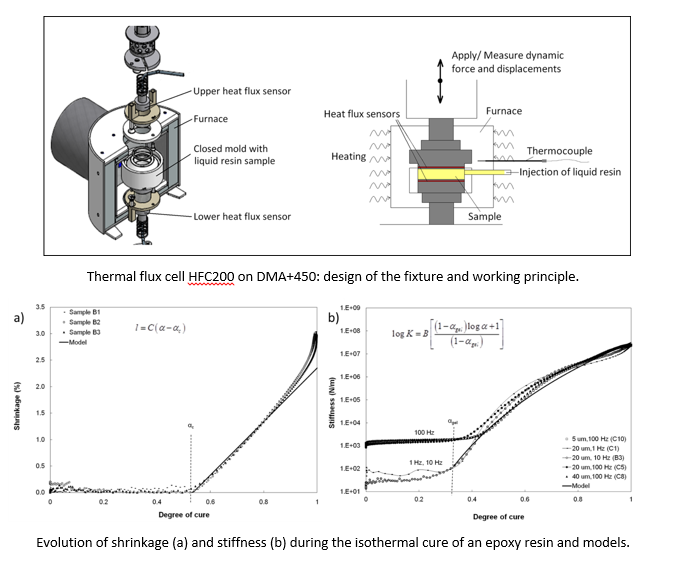

Development of novel characterization method for chemical shrinkage and thermomechanical properties with a thermal heat flux cell

A novel technique was developed that enable the characterization of the dimensional changes and evolution of mechanical properties of a resin during cure. This is achieved using an innovative in-situ device called thermal flux cell combined with a Dynamical Mechanical thermal Analyser (DMA). With this system, it is now possible to eliminate the sources of error induced while combining two or more instruments. This device consists into a mold containing the resin where the upper and lower surfaces acting as heat flux sensors (Figure 1). Changes in temperature and thermal flux are directly monitored as well as the dynamical displacement and the stiffness during the curing process. A complete study was carried out for an epoxy resin and the results of this study were the subject of conference and a publication in a journal paper. The volume and mechanical changes were derived from experimental data and linked to the degree of cure. Chemo and thermo-mechanical models were created to predict the changes in chemical shrinkage and stiffness during cure (Figure 2). The results of this study made it possible to extend this measurement principle to other materials such as aerospace resins, adhesives or prepregs.

AA

| Group members | |

| Leader: | Catherine Billotte |

| Participant: | Roland Fotsing |

| Supervisor: | Prof. Edu Ruiz |

ng aaa

fd

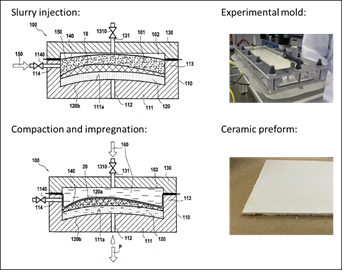

Invention of new methods for manufacturing ceramic composite materials

New manufacturing methods has been invented for ceramic composites (CMC) using flexible injection and slurry transfer molding. For flexible injection, the mold consist into a cavity and its cover is a flexible membrane. The membrane separates the impregnation and compaction chambers. The ceramic liquid slurry is injected onto the fibrous reinforcement and then the impregnation is carried out transversely. The membrane forces the fluid to impregnate through the compaction chamber that brings the pressure with a compaction fluid. The mold has certain feature such as a porous membrane at the bottom that allow draining the liquid from the slurry and maintaining the powder particles inside the texture and obtain a fibrous preform.

AA

| Group members | |

| Leader: | Catherine Billotte |

| Supervisors: | Prof. Edu Ruiz |

| Prof. Sylvain Turenne |

Roland F

Patents:

WO2016102837 – METHOD FOR MANUFACTURING A REFRACTORY PART MADE OF COMPOSITE MATERIAL

WO2016102839 – METHOD FOR MANUFACTURING A FIBROUS PREFORM FILLED WITH REFRACTIVE CERAMIC PARTICLES

WO2016102842 – METHOD FOR MANUFACTURING PART MADE OF COMPOSITE MATERIAL

FR3030502 – PROCEDE DE FABRICATION D’UNE PIECE EN MATERIAU COMPOSITE

FR3030505 – PROCEDE DE FABRICATION D’UNE PREFORME FIBREUSE CHARGEE DE PARTICULES CERAMIQUES REFRACTAIRES

FR3030503 – PROCEDE DE FABRICATION D’UNE PIECE EN MATERIAU COMPOSITE

A

A

A

Optimisation of slurry rheology and formulation for Ox-Ox and SiC-SiC ceramic composites

The manufacture of CMC by liquid injection requires optimization in the various materials composing the slurry and a deep understanding of its flow and therefore its rheology. Different studies have been carried out on oxide-oxide and SiC-SiC ceramic slurries in order to optimize the manufacturing processes. Chemicals such as dispersants, have in particular been optimized, making possible maintain of particles in suspension. The objective is to make a ceramic cake that has homogeneous distribution of the particles in the ceramic reinforcement. The maximum loading of suspensions have been also calculated using rheological models such as Maron-Pierce and Krieger-Dougherty.

A

| Group members | |

| Leader: | Catherine Billotte |

| Supervisor: | Prof. Edu Ruiz |

A

A

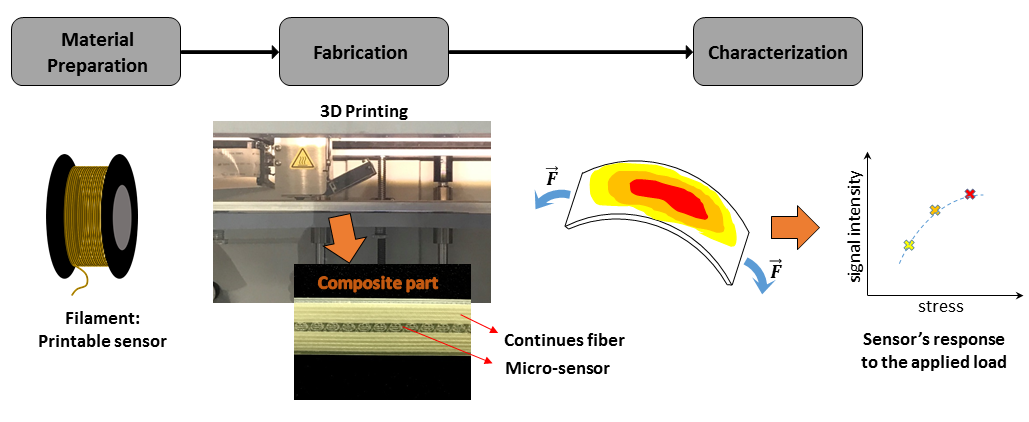

3D printing of smart nanocomposites containing remote sensors for stress monitoring

Nowadays, advanced composites are increasingly being used as replacement for traditional materials due to their exceptional mechanical properties, light weight and tailorable functionalities. Sensors integrated in composite structures can significantly enhance their performance and open the doors to new applications. Specially, there is a great interest in contactless sensing functionality as a non-destructive monitoring technique of composite parts without service interruption. This requires customized sensors depending on the application and range of monitored parameters. Also, integration of sensors in complex shaped composite parts is one of the main challenges. 3D printing (Layer Additive Manufacturing) is the next generation of manufacturing that can be a solution to the challenges faced in the fabrication of smart composites. It is a fast and high precision method to fabricate parts with complex geometries without expensive molds or waste of raw material.

The aim of this project is to fabricate continuous-fiber reinforced composites containing contactless stress monitoring sensors. Printable micro-sensors will be developed and optimized to cover the desired sensitivity range. Afterwards, they will be embedded in composite structure during the 3D printing fabrication where the role of sensor/composite interfacial modification as well as processing parameters will be studied.

AA

| Group members | |

| Leader: | Sahar Nouri |

| Supervisors: | Prof. Edu Ruiz |

| Prof. David Ménard |

aaa